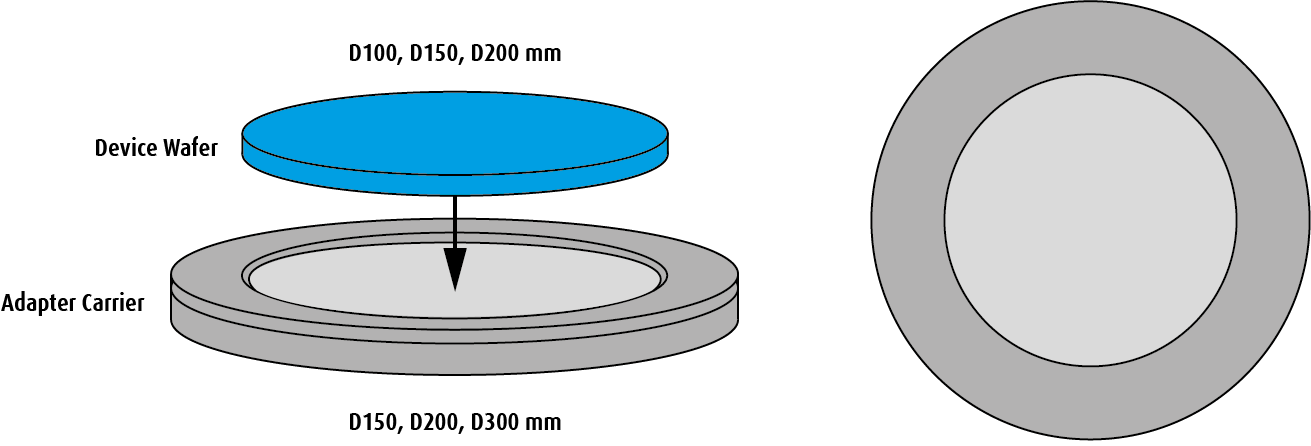

What are Adapter Carriers?

Adapter Carriers are customized tools enabling processing of smaller sized substrates or device wafers on bigger sized equipment (e.g. 6 inch device wafer on 8 inch equipment). The carrier diameter and thickness is matched to existing process tools such as thinning, dry etching, coating, implant, metal deposition, probing, etc..

What materials and sizes are available?

Adapter Carriers can be made from various materials depending on the process parameters. Majority of Adapter carriers is made from Silicon, but there are also multiple glass and quartz types as well as silicon-glass compounds available. Adapter Carriers are available up to 300mm diameter.

How do Adapter Carriers work?

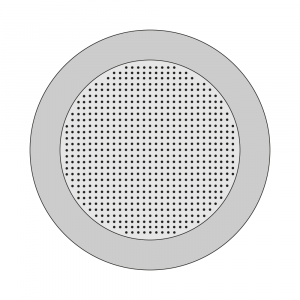

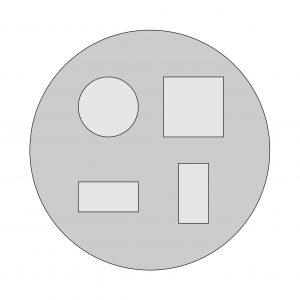

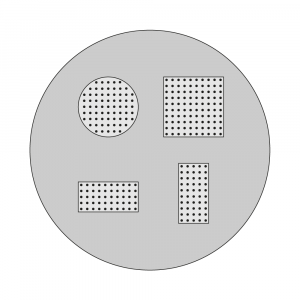

Adapter carriers do have one or more pockets in which the device wafers is placed. Typically the device wafer is not fixed in the pocket, but there are options where the wafer can be held in place by vacuum.

holes for vacuum clamping

customized pockets

customized pockets + holes

What are the benefits of using Plan Optik’s Adapter Carriers?

Smaller substrate sizes can easily be processed on lager systems without major changeovers.

Additionally Adapter Carriers can be reused multiple times. This can significantly increase the flexibility and utilization of existing wafer lines. Plan Optik offers customized high quality Adapter Carriers solutions.

Available products at Plan Optik:

Silicon Adapter Carriers

Glass and Quartz Adapter Carriers

Silicon-Glass compounds

additional customized patternings

For more information, please contact our sales engineers by e-mail or leave your e-mail address below.