What are MEMS Gyroscopes?

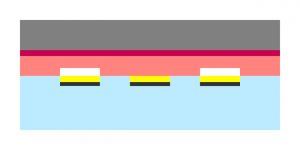

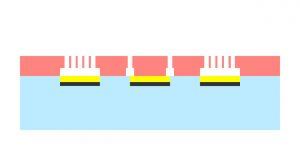

MEMS Gyroscopes are used for the detection of yaw-rate respectively angular-rate. They are manufactured by using MEMS (Microelectromechanical systems) technologies. The core part of a MEMS Gyroscope is an angular-rate sensing die based on a silicon device wafer, encapsulated by a high quality borosilicate glass wafer.

General process flow

How do MEMS Gyroscopes work?

A resonant mass is displaced when the angular velocity changes. This change can be detected capacitively.

What are MEMS Gyroscopes used for?

Automotive: ESP (electronic stability program), navigation

Aerospace: Navigation, attitude

Consumer: Gaming equipment, navigation

What are MEMS Gyroscopes glass wafers used for?

Glass wafers are a critical part in respect to the function of the entire sensor. They are used for encapsulation of the sensor. They need to ensure a long term stability, especially for critical, safety related functions in aerospace, automotive and consumer applications.

What are the advantages of Plan Optik’s glass wafers and how do they look like?

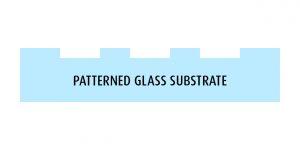

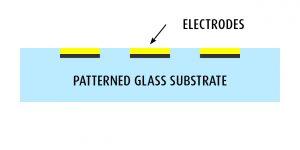

Plan Optik’s MEMS Gyroscopes glass wafers are made from a special borosilicate glass (Borofloat33®, Pyrex®, etc.) due to its thermal properties (CTE) adapted to Silicon. Additionally this glass is suitable for anodic bonding due to its chemical composition. Plan Optik is offering high quality wafers in all common diameters with an extensive thickness range. These wafers can be double side polished or patterned (cavities or through-holes).

Available products at Plan Optik:

- polished glass wafers

- MDF polished glass wafers

- Cavity glass wafers

- Through-hole glass wafers

For more information, please contact our sales engineers by e-mail or leave your e-mail address below.